SincereFirst introduces a professional-grade micro-imaging solution featuring the Raysense ES101 sensor, delivering 1000×1000@60FPS and 1000×800@75FPS output. The 3.1mm separated module integrates a 1/9" sensor with 1.4μm pixels, 140° FOV, and six white LEDs, transmitting 10bit RAW data via Type-C (

On December 2, 2025, MicroPort Robotics Group announced that its independently developed "Dragonfly Eye" stereoscopic electronic laparoscope has successfully obtained EU CE certification. This breakthrough not only marks a critical step for China's high-end surgical robot systems entering the intern

# Visual Oral Endoscope: Technical Requirements and Future Development Trends for Endoscope Camera Modules## IntroductionDriven by rising personal health consciousness and the proliferation of mobile healthcare technology, visual oral endoscopes are transitioning from professional dental clinics to

[Industry Insight] On December 1, Xishan Technology unveiled its 4K ultra-high-definition endoscope system at MEDICA International Trade Fair in Düsseldorf, Germany, drawing distributors and clinical experts from 43 countries. While seemingly a routine product showcase, this event marks a landmark m

OCHFA10 sensor, delivering 700×700@60fps (or 90fps at 400×400) with 0.4lux low-light performance. Fixed 0.418mm focal length covers 5-50mm working distance.Key advantage: Dual YUY/MJPEG output via USB2.0 UVC protocol—true plug-and-play on Windows/Linux/macOS/Android, eliminating driver development.M

On March 11, 2025, FUJIFILM Healthcare Americas Corporation announced the official commercialization of its EN-840T double-balloon enteroscopy (DBE) camera module. As a long-standing manufacturer in the endoscope module sector, this new product is specifically designed for small bowel disease diagno

For visual inspection in confined spaces, sharing field-validated specs of a 3.9mm USB endoscope module:Built on OmniVision OV9734 sensor, the module delivers stable 30FPS at 1280×720 resolution, with PureCel® backside-illuminated technology ensuring low-light sensitivity. The optical system feature

Addressing precision inspection needs in fields such as medical care, industry, and aerospace, this endoscope camera module based on the OV2740 sensor has emerged as a core selection solution, leveraging its "compact size + high reliability + wide adaptability". Key technical highlights are as follo

Product Positioning and EvolutionOCHFA10 is the official upgraded model of OVM6946. Both adopt OmniVision's CameraCubeChip® wafer-level packaging technology, specifically designed for disposable medical endoscopes. Although OCHFA10 comprehensively surpasses its predecessor in technical specification

November 26, 2025 — Feiyinuo's Vicyto-6000 endoscope system, unveiled at MEDICA 2025, sets three hard requirements for upstream module vendors: distal outer diameter <5.8mm, latency <15ms, and 120° bendability, signaling medical endoscopes' entry into the "optical-electronic-computational integratio

As a device focusing on visualization needs in narrow spaces, the 3.9mm USB Endoscope Camera Module has become a reliable choice in fields such as medical diagnosis and treatment, industrial inspection, and pet healthcare, thanks to its core performance and practical design. Below is an objective ov

In the world of industrial, medical, and inspection technologies, endoscope camera modules play a pivotal role.

In industrial settings, efficiency and precision are paramount, especially when it comes to equipment inspections.

When choosing inspection tools for industrial purposes, precision, efficiency, and reliability are key. In many industries, the ability to inspect internal components or hard-to-reach areas without dismantling equipment is crucial.

In the fast-paced world of automotive repair and diagnostics, precision, efficiency, and speed are paramount. Traditional methods of engine inspection often require time-consuming disassembly, which leads to longer downtimes and higher costs.

In today's fast-paced industrial environment, precision and efficiency are key factors driving successful operations. One technology that has significantly contributed to achieving these goals is the USB endoscope camera module.

Designed for multi-scenario precision inspection, it is equipped with the core OmniVision OCHTA10 CMOS sensor. Its ultra-slim diameter of 1.2mm±0.05mm breaks through the spatial limitations of traditional tools. Paired with an F/2.8 large aperture and an ultra-close focusing capability of 0.175mm, i

In endoscopic camera modules, lens material is a core factor determining imaging quality, durability, and cost. From a popular science perspective, this article systematically analyzes the key impacts of three materials—plastic, glass-plastic hybrid, and all-glass—on endoscopic modules, helping to u

As a manufacturer specializing in the R&D and production of endoscope camera modules, we often receive questions from customers: Why do two modules labeled with "1080P resolution, 1/4-inch CIS, 2-megapixel" have consistent core parameters but different models? Behind this lies the in-depth design co

| Availability: | |

|---|---|

| Quantity: | |

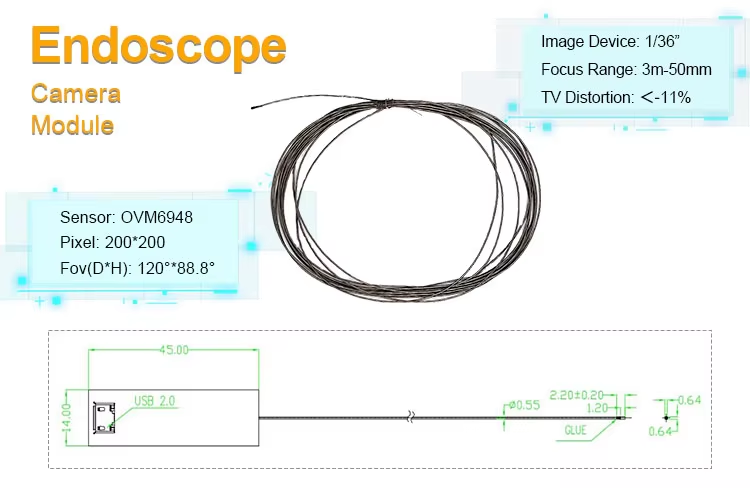

SF-C04USB-D0.9

SINCEREFIRST

This is a 0.9mm OVM6948 CMOS image sensor USB inspection endoscope camera module. Combined with a 0.3MP pixel, it can provide clear visual images in extremely narrow Spaces. The 120° wide-angle lens and adjustable focusing range from 3mm to 50mm offer a wide field of view. Equipped with a USB2.0 interface, it can transfer images/videos with a resolution of 200×200 at a speed of 30fps per second. It is widely applicable to the fields of industrial pipeline flaw detection, metal fatigue testing, and medical minimally invasive surgical lamps. |  |

Product Advantage ◢

Micro-size design: The volume advantage brought by a diameter of 0.9mm allows it to enter any narrow space or miniaturized equipment.

High-definition image details: With 0.3MP pixels and a focal length of 0.175mm, it can capture clear images at the closest distance to the object.

Wide field of view: The 120° wide-angle lens, combined with an adjustable focusing range of 3mm to 50mm, can maintain a broad field of view even when shooting at a close enough distance.

Technical Parameters ◢

Product Name | 0.9mm USB inspection endoscope camera module |

Image Device | 1/36” |

Effective Picture Element | 200(H)*200(V) |

Output Interface | USB2.0 |

Frame Rate | 30fps |

S/N Ratio | >34.4dB |

Focus Range | 3mm-50mm |

Power Supply | 4.8~5.2V |

Operating Tempeture | -20℃~70℃ |

Lens | 120°*88.8° |

Product Uses ◢

Neurointerventional guidewire : Catheter integration module with a diameter of ≤1.0mm for cerebral angiography and thrombus clearance, transmitting intracranial images in real time through the area of vascular stenosis.

Microelectronic soldering quality inspection probe : Integrated into chip mounting equipment to capture collapse defects and bridging abnormalities of ball array (BGA) at 3mm distance.

Oil and gas pipeline corrosion detection robot : Equipped with micro-crawling device, enter ≤1mm weld seam to capture high-definition image of metal fatigue crack.

FAQ ◢

1. Why is low illumination performance important for endoscope modules?

In case of insufficient light in the body or pipeline environment, the module needs a high sensitivity sensor and a large aperture lens, and the noise reduction algorithm ensures the clarity of the dark field. Some products use infrared fill light or HDR technology to improve low light performance.

2. What is the significance of the depth of field range of the module?

Large depth of field can clearly show near and far objects at the same time, reduce the need for frequent focusing, suitable for endoscopic surgery; Shallow depth of field is used to highlight specific plane details, such as skin inspection.

3. How to achieve waterproof and sterilization design?

The medical-grade module adopts IP68 waterproof seal, the shell material is resistant to high temperature and pressure, and can withstand 134°C steam sterilization. Industrial modules may require only a splash proof design.

4. What are the mainstream diameters of endoscope module lenses?

Medical field : 5-6mm is the mainstream specification of disposable endoscope, which can enter the human body through the nostril/mouth; ≤2.8mm probe is suitable for extremely narrow Spaces such as valve chambers.

Industrial field : The standard is 3-12mm, among which 5.5mm diameter with 450,000 pixels is a common industrial module specification; Φ4-6mm probe suitable for inspection of precision parts such as fuel nozzles.

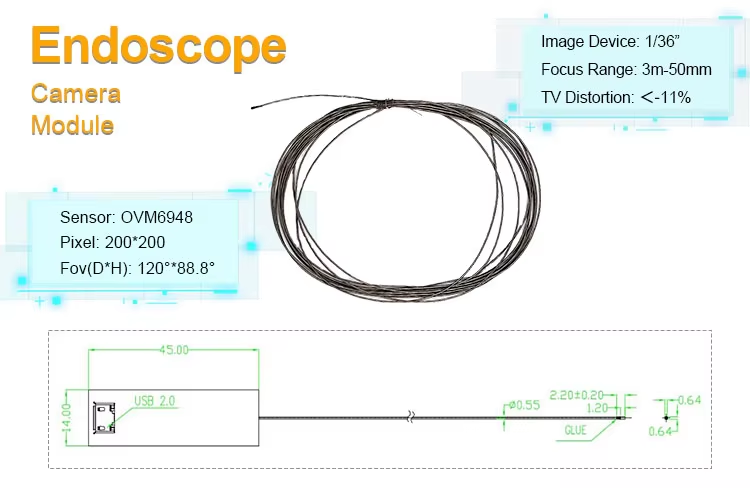

This is a 0.9mm OVM6948 CMOS image sensor USB inspection endoscope camera module. Combined with a 0.3MP pixel, it can provide clear visual images in extremely narrow Spaces. The 120° wide-angle lens and adjustable focusing range from 3mm to 50mm offer a wide field of view. Equipped with a USB2.0 interface, it can transfer images/videos with a resolution of 200×200 at a speed of 30fps per second. It is widely applicable to the fields of industrial pipeline flaw detection, metal fatigue testing, and medical minimally invasive surgical lamps. |  |

Product Advantage ◢

Micro-size design: The volume advantage brought by a diameter of 0.9mm allows it to enter any narrow space or miniaturized equipment.

High-definition image details: With 0.3MP pixels and a focal length of 0.175mm, it can capture clear images at the closest distance to the object.

Wide field of view: The 120° wide-angle lens, combined with an adjustable focusing range of 3mm to 50mm, can maintain a broad field of view even when shooting at a close enough distance.

Technical Parameters ◢

Product Name | 0.9mm USB inspection endoscope camera module |

Image Device | 1/36” |

Effective Picture Element | 200(H)*200(V) |

Output Interface | USB2.0 |

Frame Rate | 30fps |

S/N Ratio | >34.4dB |

Focus Range | 3mm-50mm |

Power Supply | 4.8~5.2V |

Operating Tempeture | -20℃~70℃ |

Lens | 120°*88.8° |

Product Uses ◢

Neurointerventional guidewire : Catheter integration module with a diameter of ≤1.0mm for cerebral angiography and thrombus clearance, transmitting intracranial images in real time through the area of vascular stenosis.

Microelectronic soldering quality inspection probe : Integrated into chip mounting equipment to capture collapse defects and bridging abnormalities of ball array (BGA) at 3mm distance.

Oil and gas pipeline corrosion detection robot : Equipped with micro-crawling device, enter ≤1mm weld seam to capture high-definition image of metal fatigue crack.

FAQ ◢

1. Why is low illumination performance important for endoscope modules?

In case of insufficient light in the body or pipeline environment, the module needs a high sensitivity sensor and a large aperture lens, and the noise reduction algorithm ensures the clarity of the dark field. Some products use infrared fill light or HDR technology to improve low light performance.

2. What is the significance of the depth of field range of the module?

Large depth of field can clearly show near and far objects at the same time, reduce the need for frequent focusing, suitable for endoscopic surgery; Shallow depth of field is used to highlight specific plane details, such as skin inspection.

3. How to achieve waterproof and sterilization design?

The medical-grade module adopts IP68 waterproof seal, the shell material is resistant to high temperature and pressure, and can withstand 134°C steam sterilization. Industrial modules may require only a splash proof design.

4. What are the mainstream diameters of endoscope module lenses?

Medical field : 5-6mm is the mainstream specification of disposable endoscope, which can enter the human body through the nostril/mouth; ≤2.8mm probe is suitable for extremely narrow Spaces such as valve chambers.

Industrial field : The standard is 3-12mm, among which 5.5mm diameter with 450,000 pixels is a common industrial module specification; Φ4-6mm probe suitable for inspection of precision parts such as fuel nozzles.