Research on Lightweight Integration of Low-Power Imaging Modules in Children’s Educational MicroscopesAbstractScientific enlightenment tools designed for young children must ensure both operational safety and engagement while providing intuitive and clear observational experiences. Traditional optic

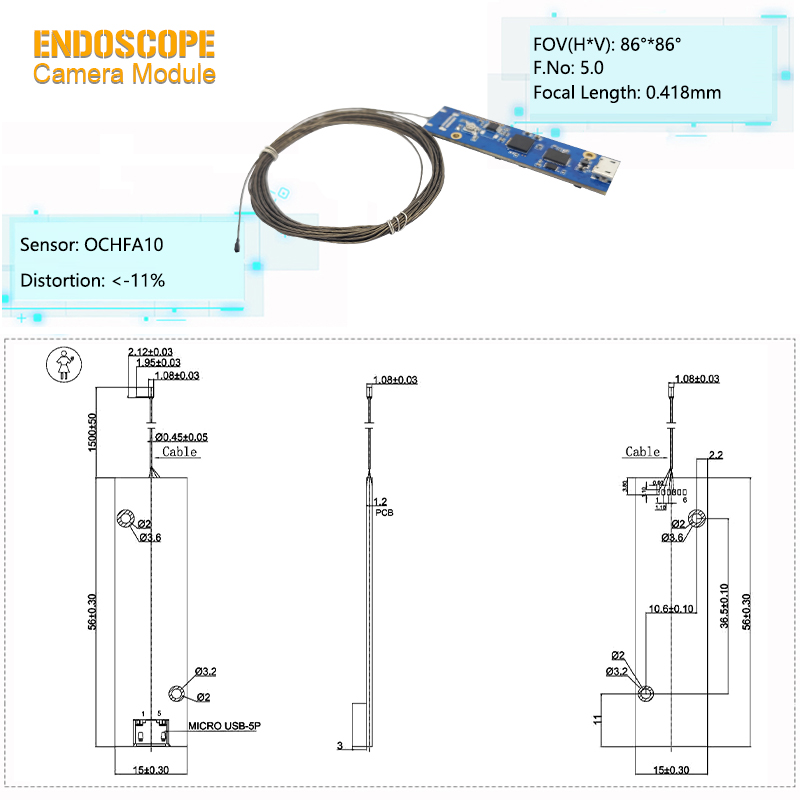

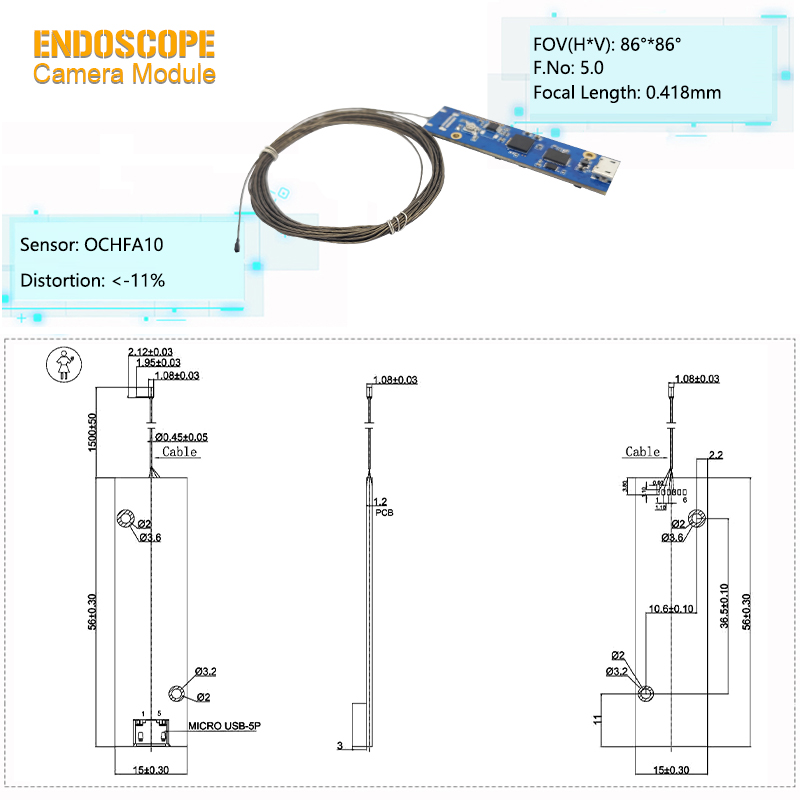

Deconstructing the Design Philosophy and Application Boundaries of a Compact Endoscope Camera ModuleAgainst the backdrop of the increasing miniaturization and integration of professional-grade image acquisition equipment, a compact endoscope camera module tailored for close-range, confined-space ins

Technical Evolution and Clinical Empowerment of Hysteroscopic Imaging Systems Abstract With the deepening application of minimally invasive diagnostic and therapeutic techniques in gynecology, hysteroscopy has become a core tool for diagnosing and treating intrauterine lesions. Its clinical efficacy

January 27, 2026 — Mindray has been granted a patent for a novel "endoscopic camera and endoscopic camera system," introducing a dedicated anti-collision terminal structure. This innovation directly addresses a critical and often overlooked challenge in the precise assembly process of high-end endos

How to Select the Right Ultra-Short-Throw HD Camera Module for Confined Spaces? When integrating vision systems into industrial endoscopes, pipeline inspection tools, minimally invasive surgical instruments, or compact devices, choosing the right camera module is critical to success. Faced with chal

{"text":"The medical imaging landscape is rapidly shifting from Full HD (1080p) to Ultra HD (4K) as the new gold standard for high-end visualization. While marketing departments often demand 4K specifications to compete in premium segments, engineering teams face a complex reality. Integrating a hig

{"text":"In minimally invasive surgery (MIS), the monitor acts as the surgeon’s eyes, introducing a unique physiological challenge known as \"Hand-Eye Decoupling.\" Even millisecond delays between a physical hand movement and the visual confirmation on the screen can disrupt surgical flow. This late

{"text":"The landscape of medical and industrial inspection is rapidly shifting. We are moving away from bulky, cart-based units toward handheld, battery-operated IoT devices. This transition empowers professionals to perform diagnostics in remote or constrained environments with unprecedented ease.

{"text":"The medical device industry is currently navigating a fundamental restructuring. For decades, endoscopy relied on the \"asset\" model, where hospitals purchased expensive capital equipment designed to last for years. Today, the sector is rapidly shifting toward a \"consumable\" model, drive

{"text":"Accessing sub-2mm cavities presents a significant engineering hurdle across both medical and industrial sectors. Surgeons navigating bronchial peripheries and maintenance crews inspecting turbine blade cooling channels often face a physical wall: traditional 3mm borescopes simply cannot fit

January 19, 2026 — Ofilm has announced the completion of its 1×1mm ultra-miniature endoscopic camera module, marking a pivotal step in advancing minimally invasive medical diagnostics. This breakthrough addresses a core challenge in the industry by dramatically reducing the size constraints of tradi

Building Competitive Advantage in Compact Industrial Vision: Strategic Considerations for Micro HD Camera ModulesWith rapid advancements in industrial automation, endoscopic inspection, and consumer electronics, market demand for ultra-compact, highly integrated, reliable, and durable HD camera modu

In the optical technology iteration of camera modules, liquid lenses, as a new type of component breaking the limitations of traditional solid-state lenses, are gradually changing the design logic and application scenarios of modules with their dynamically adjustable optical characteristics. Unlike

From "Seeing" to "Seeing Clearly, Understanding and Penetrating"In the field of medical devices, the development of endoscope technology has profoundly changed the way of diagnosis and minimally invasive surgery. As the "eyes" of the endoscope system, camera modules are undergoing a profound transfo

The Profound Transformation of Medical Imaging Through the Lens of 10MP Endoscope ModulesIn an era where precision medicine and minimally invasive surgery are increasingly prevalent, endoscopes serve as the doctor's “extended eyes.” Their technological evolution directly impacts diagnostic accuracy

When Full HD resolution becomes a standard specification for miniature image sensors, Rayshun Micro's ES101 and OmniVision's OH01A10 have developed distinctly different technical characteristics within the same resolution framework.

5MP HD autofocus module empowers the Rhino XT duct cleaning system: Clear vision drives professional cleaning and transparent service.In professional HVAC duct cleaning, service value lies not only in cleaning results but also in the visualization, verifiability, and trustworthiness of the cleaning

Industry Analysis of Miniature HD Camera Modules: Core Perception Components in the Era of Intelligent VisionIntroductionAmidst the wave of universal connectivity and intelligent upgrades, machine vision has emerged as a pivotal technology empowering countless industries. As the “eyes” of visual sys

The development of high-resolution industrial endoscopes with an extremely small diameter is not merely a matter of component miniaturization, but a system-level engineering challenge that necessitates a sophisticated trade-off among optics, sensor performance, mechanical structure, and signal integ

High-Definition Micro Modules Empower Flexible Veterinary EndoscopesIn modern veterinary diagnostics, achieving precise internal examination, foreign body removal, and diagnostic sampling with minimal trauma is crucial for enhancing animal welfare and clinical standards—especially when dealing with

| Availability: | |

|---|---|

| Quantity: | |

SF-OCHFA20-2500mm+SF-YL428-V1.1

SINCEREFIRST

This is a 1.5mm-diameter wide-angle 720P sensor OCHFA20 endoscope camera module. Through the precise combination of a 120° ultra-wide field of view and a 1.5mm ultra-fine lens diameter, it achieves a perfect balance between "penetrating narrow spaces" and "expanding observation range". Equipped with comprehensive high-performance parameters, it serves as a core solution for precise observation across multiple fields. The module is integrated with an OmniVision OCHFA20 CMOS color image sensor with 0.5MP pixels. The ultra-small 1/18-inch sensor size and 1.008 μm×1.008 μm pixel specifications not only ensure light-sensing efficiency and imaging details but also provide a hardware foundation for the design of the 1.5mm ultra-fine lens. It can easily penetrate gaps in precision equipment, tiny cavities, and other areas that traditional cameras cannot reach; meanwhile, the 120° wide field of view breaks the limitation of "small lens = narrow field of view", significantly reducing observation blind spots. The module supports stable output of 720×720 resolution and 720P@30FPS, with smooth dynamic images free of motion blur. Combined with the manual focus function, it can accurately lock onto target details within a wide coverage range. Adopting a Separated design, it connects to the DSP board via a USB 6PIN header and then outputs signals through a Type-C interface. It supports USB 2.0 speed and UVC protocol, and is compatible with mainstream operating systems such as Windows, Mac, and Linux without the need for additional drivers, enabling flexible and efficient connection and deployment. The module is manufactured using SMT technology and AA (Active Alignment) process, ensuring the consistency and stability of mass-produced products. It has also passed multiple international testing and certifications including CE, FCC, RoHS, and Reach, fully meeting the compliance and reliability requirements for multi-scenario use. |  |

Balance between Field of View and Diameter: The 1.5mm ultra-fine lens diameter ensures accessibility in narrow spaces, while the 120° ultra-wide field of view realizes "small probe, large coverage". It reduces observation blind spots without moving the probe, improving detection efficiency.

HD and Smooth Image Quality: Equipped with 0.5MP pixels and 720×720 resolution, it clearly presents target details. The 720P@30FPS frame rate ensures no motion blur in dynamic observation, adapting to real-time detection needs.

Flexible Adaptation to Scenarios: The manual focus function can accurately adjust clarity according to the observation distance, which not only meets long-distance wide-area scanning but also realizes close-range detail magnification, adapting to different observation requirements.

Flexible Integration: The Separated architecture and Type-C interface enable the module to be easily adapted to various detection equipment, greatly enhancing the integration flexibility and usability of industrial endoscope systems.

Stable Process and Quality: SMT technology and AA process ensure product consistency; multiple international certifications cover major global markets. The module can withstand use in complex environments, ensuring long-term reliability.

Aerospace Precision Component Inspection: In the inspection of aircraft engines and aerospace precision components, it can not only pass through narrow inspection holes but also provide a broad internal field of view, significantly improving detection efficiency and accuracy.

Minimally Invasive Medical Surgery Assistance: In orthopedic arthroscopic surgery and otolaryngological sinus minimally invasive surgery, it can not only pass through minimally invasive instrument channels but also provide a wide surgical field of view, reducing wound damage while improving surgical precision.

Electronic Chip Packaging and Inspection: In the packaging inspection of mobile phone SoC chips and automotive micro-sensors, it can not only pass through chip packaging gaps but also provide a complete field of view of solder joints and circuits, quickly identifying packaging defects and ensuring product yield.

Ancient Architecture and Cultural Relic Restoration Inspection: In the inspection of mortise and tenon gaps in ancient wooden structures and fine cracks in ceramic cultural relics, it can not only penetrate narrow gaps of cultural relics but also provide a complete field of view of the internal structure, avoiding damage to cultural relics while providing accurate basis for restoration.

In-depth Maintenance of Household and Commercial Equipment: In the maintenance of air conditioner evaporator fin gaps, refrigerator capillary pipelines, and printer nozzle ink circuits, it can not only pass through narrow maintenance channels of equipment but also provide a comprehensive field of view of internal components, reducing maintenance difficulty and improving fault location efficiency.

Product Name | 1.5mm Endoscope Camera Module |

Image Sensor | OCHFA20 CMOS Sensor |

Pixel | 0.5MP |

Diameter | 1.5mm |

View Angle | D120° |

Sensor Size | 1/18 Inch |

Pixel Size | 1.008μmx1.008μm |

Focus Type | Fixed Focus |

Interface | USB 2.0 |

Feature | Medical Endoscope Camera Module |

It supports USB 2.0 speed and UVC protocol, compatible with Windows, Mac, and Linux. It connects via USB 6PIN header (to DSP board) and outputs via Type-C, no extra drivers needed.

It has 0.5MP pixels, supports 720×720 resolution, and outputs 720P@30FPS—ensuring smooth dynamic images with no motion blur, plus manual focus for precise detail capture.

Yes, it fits both. Key uses include aerospace precision component inspection, minimally invasive medical surgery, electronic chip packaging testing, and more—backed by CE, FCC, RoHS, and Reach certifications.

This is a 1.5mm-diameter wide-angle 720P sensor OCHFA20 endoscope camera module. Through the precise combination of a 120° ultra-wide field of view and a 1.5mm ultra-fine lens diameter, it achieves a perfect balance between "penetrating narrow spaces" and "expanding observation range". Equipped with comprehensive high-performance parameters, it serves as a core solution for precise observation across multiple fields. The module is integrated with an OmniVision OCHFA20 CMOS color image sensor with 0.5MP pixels. The ultra-small 1/18-inch sensor size and 1.008 μm×1.008 μm pixel specifications not only ensure light-sensing efficiency and imaging details but also provide a hardware foundation for the design of the 1.5mm ultra-fine lens. It can easily penetrate gaps in precision equipment, tiny cavities, and other areas that traditional cameras cannot reach; meanwhile, the 120° wide field of view breaks the limitation of "small lens = narrow field of view", significantly reducing observation blind spots. The module supports stable output of 720×720 resolution and 720P@30FPS, with smooth dynamic images free of motion blur. Combined with the manual focus function, it can accurately lock onto target details within a wide coverage range. Adopting a Separated design, it connects to the DSP board via a USB 6PIN header and then outputs signals through a Type-C interface. It supports USB 2.0 speed and UVC protocol, and is compatible with mainstream operating systems such as Windows, Mac, and Linux without the need for additional drivers, enabling flexible and efficient connection and deployment. The module is manufactured using SMT technology and AA (Active Alignment) process, ensuring the consistency and stability of mass-produced products. It has also passed multiple international testing and certifications including CE, FCC, RoHS, and Reach, fully meeting the compliance and reliability requirements for multi-scenario use. |  |

Balance between Field of View and Diameter: The 1.5mm ultra-fine lens diameter ensures accessibility in narrow spaces, while the 120° ultra-wide field of view realizes "small probe, large coverage". It reduces observation blind spots without moving the probe, improving detection efficiency.

HD and Smooth Image Quality: Equipped with 0.5MP pixels and 720×720 resolution, it clearly presents target details. The 720P@30FPS frame rate ensures no motion blur in dynamic observation, adapting to real-time detection needs.

Flexible Adaptation to Scenarios: The manual focus function can accurately adjust clarity according to the observation distance, which not only meets long-distance wide-area scanning but also realizes close-range detail magnification, adapting to different observation requirements.

Flexible Integration: The Separated architecture and Type-C interface enable the module to be easily adapted to various detection equipment, greatly enhancing the integration flexibility and usability of industrial endoscope systems.

Stable Process and Quality: SMT technology and AA process ensure product consistency; multiple international certifications cover major global markets. The module can withstand use in complex environments, ensuring long-term reliability.

Aerospace Precision Component Inspection: In the inspection of aircraft engines and aerospace precision components, it can not only pass through narrow inspection holes but also provide a broad internal field of view, significantly improving detection efficiency and accuracy.

Minimally Invasive Medical Surgery Assistance: In orthopedic arthroscopic surgery and otolaryngological sinus minimally invasive surgery, it can not only pass through minimally invasive instrument channels but also provide a wide surgical field of view, reducing wound damage while improving surgical precision.

Electronic Chip Packaging and Inspection: In the packaging inspection of mobile phone SoC chips and automotive micro-sensors, it can not only pass through chip packaging gaps but also provide a complete field of view of solder joints and circuits, quickly identifying packaging defects and ensuring product yield.

Ancient Architecture and Cultural Relic Restoration Inspection: In the inspection of mortise and tenon gaps in ancient wooden structures and fine cracks in ceramic cultural relics, it can not only penetrate narrow gaps of cultural relics but also provide a complete field of view of the internal structure, avoiding damage to cultural relics while providing accurate basis for restoration.

In-depth Maintenance of Household and Commercial Equipment: In the maintenance of air conditioner evaporator fin gaps, refrigerator capillary pipelines, and printer nozzle ink circuits, it can not only pass through narrow maintenance channels of equipment but also provide a comprehensive field of view of internal components, reducing maintenance difficulty and improving fault location efficiency.

Product Name | 1.5mm Endoscope Camera Module |

Image Sensor | OCHFA20 CMOS Sensor |

Pixel | 0.5MP |

Diameter | 1.5mm |

View Angle | D120° |

Sensor Size | 1/18 Inch |

Pixel Size | 1.008μmx1.008μm |

Focus Type | Fixed Focus |

Interface | USB 2.0 |

Feature | Medical Endoscope Camera Module |

It supports USB 2.0 speed and UVC protocol, compatible with Windows, Mac, and Linux. It connects via USB 6PIN header (to DSP board) and outputs via Type-C, no extra drivers needed.

It has 0.5MP pixels, supports 720×720 resolution, and outputs 720P@30FPS—ensuring smooth dynamic images with no motion blur, plus manual focus for precise detail capture.

Yes, it fits both. Key uses include aerospace precision component inspection, minimally invasive medical surgery, electronic chip packaging testing, and more—backed by CE, FCC, RoHS, and Reach certifications.