Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

5MP HD autofocus module empowers the Rhino XT duct cleaning system: Clear vision drives professional cleaning and transparent service.

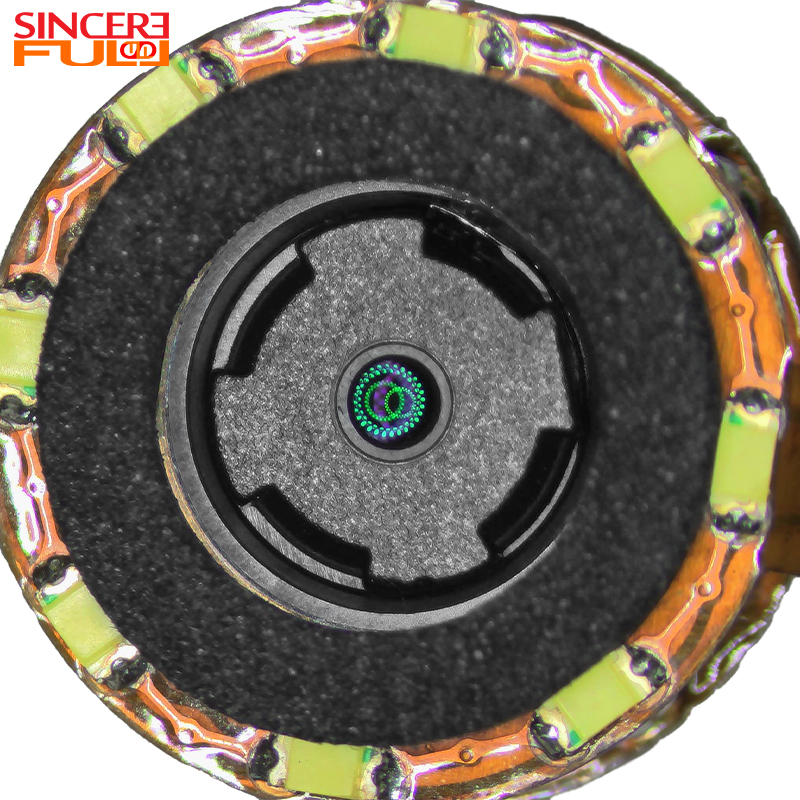

In professional HVAC duct cleaning, service value lies not only in cleaning results but also in the visualization, verifiability, and trustworthiness of the cleaning process. The Rhino XT duct cleaner seamlessly integrates ,high-speed mechanical cleaning with high-definition visual inspection, enabling service providers and customers to jointly “see” the results of every cleaning job. The success of this innovative model hinges critically on whether its front-end visual system can reliably deliver clear, real-time internal imagery within dimly lit, dusty, and confined duct spaces—while adapting to varying duct diameters and debris distances. Our high-definition auto-focus endoscopic camera module, optimized for complex environmental visual inspection, precisely meets the core requirements of the Rhino XT system. Featuring 5-megapixel HD resolution, auto-focus capability, wide-field imaging, and a compact, rugged design, it serves as the reliable visual core enabling “visualized cleaning services.”

I. High-Definition Resolution and Wide Dynamic Range Imaging: Delivering Irrefutable Before-and-After Cleaning Evidence

The professionalism and added value of pipeline cleaning services rely on clear, objective visual evidence. Clients demand to see details of stubborn dust deposits, oil stains, and even microbial mold spots being thoroughly removed. This places high demands on an imaging system's resolution and detail rendering capabilities.

This module features a high-performance 1/5-inch CMOS sensor, supporting 2592 x 1944 (approximately 5 megapixel) high-definition static image output. High resolution ensures clear identification of pipe welds, inner wall textures, and deposit formations during playback or screenshots on tablets or mobile devices, providing pixel-level detail for pre- and post-cleaning comparison. Combined with automatic exposure, white balance, and gain control, the module intelligently adapts to complex light reflection conditions inside pipes. This ensures color-accurate, balanced images across diverse pipe materials (e.g., metal, fiberglass) and dirt colors, making cleaning results more intuitive and credible.

II. Autofocus Functionality and Wide Working Distance: Precise Observation Adapted to Variable Pipe Diameters and Contaminants

During cleaning operations, the distance between the camera and the pipe wall fluctuates due to changes in pipe diameter, navigating bends, and targeted inspections of specific contamination points. Fixed-focus cameras cannot maintain optimal clarity at all distances, compromising observation quality.

This module integrates an autofocus system with a range spanning 5 centimeters to infinity. This capability is crucial: when the cleaning head traverses larger pipe diameters, the camera automatically focuses on distant pipe walls for comprehensive scans; when close-up inspection of a contamination point or brush effectiveness is required, it rapidly shifts focus to capture microscopic details of debris. The autofocus function ensures operators consistently obtain sharp images throughout the cleaning path—whether capturing overall overviews or detailed close-ups—enabling precise assessment of cleaning effectiveness and detection of potentially overlooked residual areas.

III. Wide Field of View and Large Aperture Design: Ensuring Extensive Clear Vision in Dimly Lit Pipes

Pipe interiors typically lack natural light entirely and feature confined spaces. The camera must cover the widest possible observation range under limited supplementary lighting conditions while maintaining overall brightness and clarity.

This module's lens offers a 72° wide field of view, capturing a larger area of the pipe's inner wall in a single frame. This reduces blind spots and enhances inspection efficiency. Additionally, its F2.8 large aperture design significantly increases light transmission. Paired with the module's integrated high-brightness white LED illuminator (color temperature 6000-6500K, simulating daylight), it delivers bright, uniform illumination within completely dark pipelines while outputting a bright, low-noise real-time video stream. The expansive, clear field of view allows operators to easily monitor overall cleaning progress and promptly identify hidden damage or anomalies.

IV. Compact, Rugged Design with Industrial-Grade Reliability: Withstanding Demanding Cleaning Environments

Pipe cleaning machines operate under conditions of intense vibration, dust ingress, and potential temperature fluctuations. The integrated camera module must feature a compact structure for seamless integration while delivering exceptional physical protection and environmental adaptability.

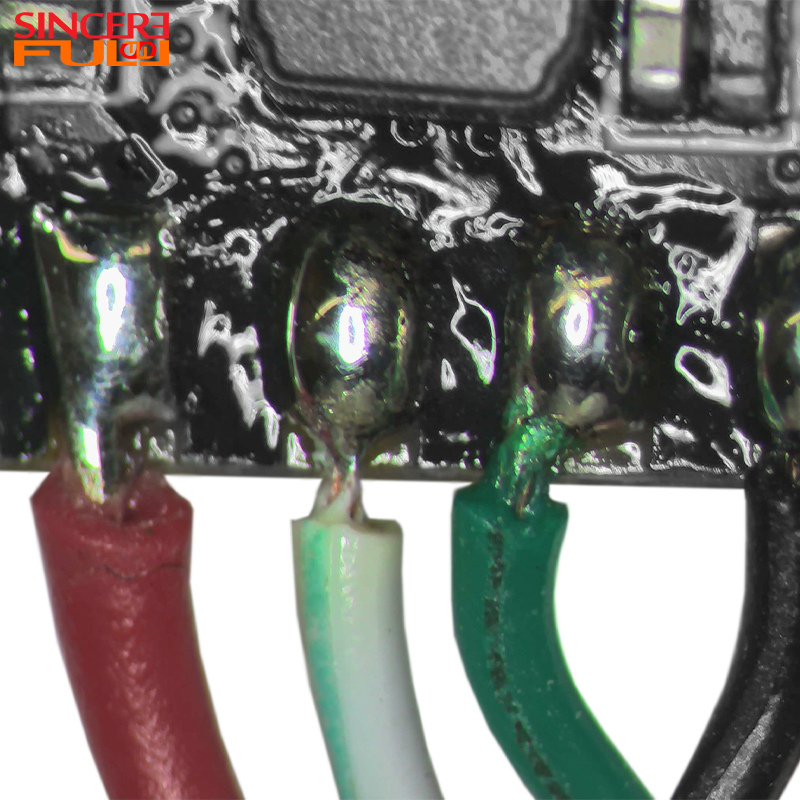

This module employs a highly integrated and compact design, featuring a small footprint that easily fits within the limited space at the front end of Rhino XT cleaning equipment. Its robust construction withstands continuous vibration during operation and occasional minor impacts. A wide operating temperature range of 0°C to +60°C ensures stable performance across different seasons and geographical environments, both indoors and outdoors. Additionally, its standard USB 2.0 interface ensures strong compatibility and stable connectivity, reliably transmitting high-definition video streams to a detachable tablet. This guarantees continuous and stable real-time preview and recording functions, meeting the reliability demands of professional equipment during prolonged, high-load operations.

In summary: this high-definition autofocus endoscope camera module empowers premium pipeline cleaning systems like Rhino XT with robust visual intelligence. It delivers detailed evidence through high-resolution imaging, adapts to varying observation distances with autofocus capability, ensures imaging in dim environments via a wide field of view and large aperture design, and withstands harsh conditions through its compact, rugged industrial build quality. Its deep integration transforms pipe cleaning from a back-office task reliant on experience and intuition into a modern professional service characterized by transparent processes, visible results, and verifiable quality. This significantly enhances service providers' professional credibility, customer trust, and market competitiveness, leading the HVAC cleaning industry toward upgraded digital and visual service standards.